Product Description

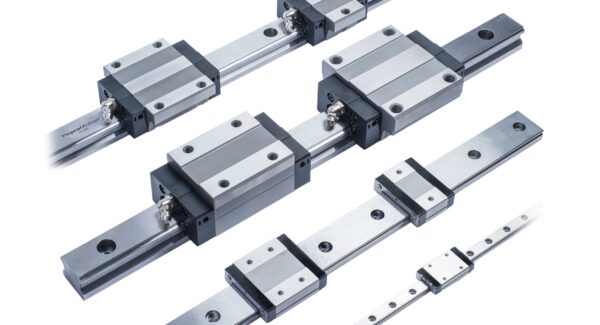

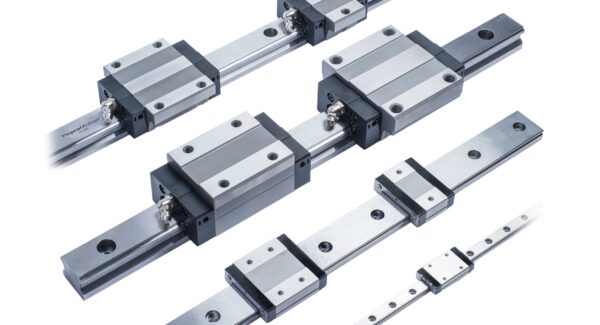

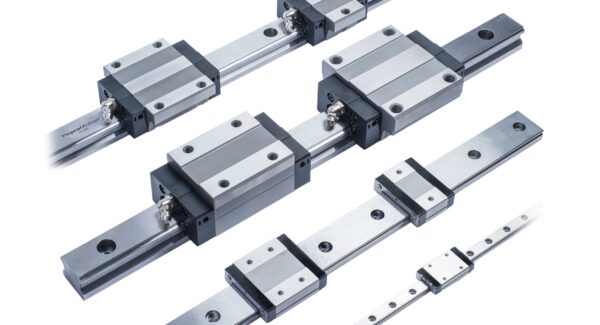

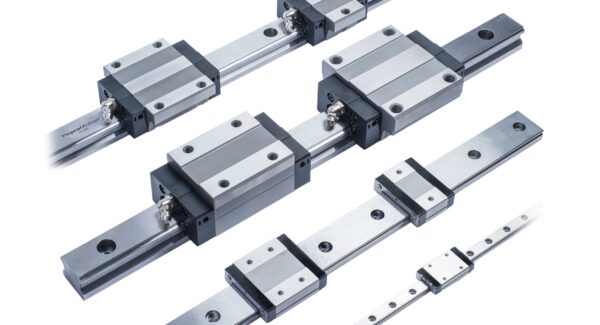

High precision linear guide rail EGH25CA EGH25SA rail length 4000mm

Product Description

low assembly linear guide

| size | EGH25CA, EGH25SA | EGW25CA, EGW25SA |

| length of rail | 1000mm | maximum 4000mm |

| production time | 5-15 days | |

| factory sale | yes |

Detailed Photos

Product Parameters

Packaging & Shipping

Company Profile

ZheJiang SAIR MECHANICAL XIHU (WEST LAKE) DIS. CO.,LTD

ZheJiang SAIR IMPORT&EXPORT TRADING CO.,LTD

ZheJiang Sair group has 2 subsidiaries, 1 is ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd, which is mainly responsible for the production, and the other 1 is ZheJiang SAIR IMPORT&EXPORT TRADING CO.,LTD., which functions as our platform of international business.

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd is 1 of the largest linear guide and ball screw manufacturer in China. With strong technical strength, advanced production equipments, and perfect after-sale services, our company is the leading precision machinery manufacturer, which have research and development, manufacturing, sales, service all in one. Our high-quality products are not only popular all over the country, but also exported to Europe, Americas, Southeast Asia, Africa etc. , totally more than 70 countries globally. Our products have good performance and are highly trusted and admired by all the domestic & overseas customers.

Our Advantages

Welcome your inquiry when you have any purchase plan of CNC parts!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane |

|---|---|

| Material: | Steel |

| Structure: | Tyre Crane |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample according to customer′s requirements

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the role of linear rails in reducing friction and wear in linear motion applications?

Linear rails play a pivotal role in reducing friction and wear in linear motion applications through several key mechanisms:

- 1. Precision Design: Linear rails are precision-engineered with specific profiles and tolerances. The precise design minimizes contact points between the rail and the carriage, reducing friction and wear to a minimum during linear motion.

- 2. Rolling Contact: Many linear rails utilize rolling contact elements, such as recirculating ball bearings or roller bearings. These elements roll along the profiled surface of the rail, significantly reducing friction compared to sliding contact. Rolling contact also distributes the load evenly, further minimizing wear on specific points.

- 3. Low-Friction Coatings: Some linear rails feature low-friction coatings on their surfaces. These coatings, often made of materials like Teflon or similar compounds, create a smooth and slippery surface, reducing the coefficient of friction. This results in smoother linear motion and less wear on the rail and carriage components.

- 4. Lubrication: Proper lubrication is essential for reducing friction and wear in linear motion systems. Lubricants applied to the rolling elements or the rail surface create a thin film that separates the moving parts, minimizing direct contact and friction. Regular lubrication intervals are crucial for maintaining optimal performance and extending the lifespan of the linear rail system.

- 5. Sealing Mechanisms: Linear rails often incorporate sealing mechanisms to protect against contaminants. Dust, debris, and moisture can contribute to increased friction and wear. Effective sealing prevents the ingress of contaminants, preserving the integrity of the rail and reducing wear on critical components.

- 6. Material Selection: The choice of materials for both the rail and carriage components influences friction and wear. High-quality materials with good wear resistance, such as hardened steel or specialized alloys, contribute to the long-term durability of the linear rail system.

- 7. Regular Maintenance: Implementing a regular maintenance schedule is crucial for reducing friction and wear. Inspections, cleaning, and lubrication ensure that the linear rail system operates smoothly and efficiently. Identifying and addressing any signs of wear early can prevent more significant issues and extend the overall lifespan of the system.

By incorporating these design features and maintenance practices, linear rails effectively minimize friction and wear in linear motion applications. This not only enhances the efficiency and accuracy of the system but also contributes to the long-term reliability and durability of the linear rail.

Can you explain the principles behind linear rail operation and load-bearing capabilities?

The operation of linear rails and their load-bearing capabilities are governed by fundamental principles:

1. Rolling Contact: Linear rails typically utilize rolling contact elements, such as recirculating ball or roller bearings, between the rail and the carriage. These elements reduce friction and enable smooth motion by rolling along the profiled surface of the rail.

2. Profiled Rail Design: The rail is designed with a specific profile, often featuring raceways for the rolling elements. This profile provides guidance to the carriage, ensuring that it moves along a predetermined path without deviations.

3. Load Distribution: The load-bearing capabilities of linear rails are achieved through the distribution of the applied load across the rolling elements. This design allows for the effective support of loads, both radial and axial, while minimizing stress on individual components.

4. Rigidity: Linear rails are designed to be rigid, preventing deflection or bending during operation. This rigidity is essential for maintaining accuracy and precision, especially in applications where high loads or forces are involved.

5. Lubrication: Proper lubrication is crucial for reducing friction and minimizing wear between the rolling elements and the rail. Lubrication also helps dissipate heat generated during operation, contributing to the overall efficiency and longevity of the linear rail system.

6. Materials and Construction: The materials used in the construction of linear rails, such as hardened steel or reinforced alloys, contribute to their load-bearing capabilities. The choice of materials ensures durability and resistance to wear under various operating conditions.

Overall, the combination of rolling contact, profiled rail design, load distribution, rigidity, lubrication, and appropriate materials enables linear rails to operate efficiently and support varying loads in industrial applications. Understanding these principles is essential for selecting the right linear rail system based on the specific requirements of a given application.

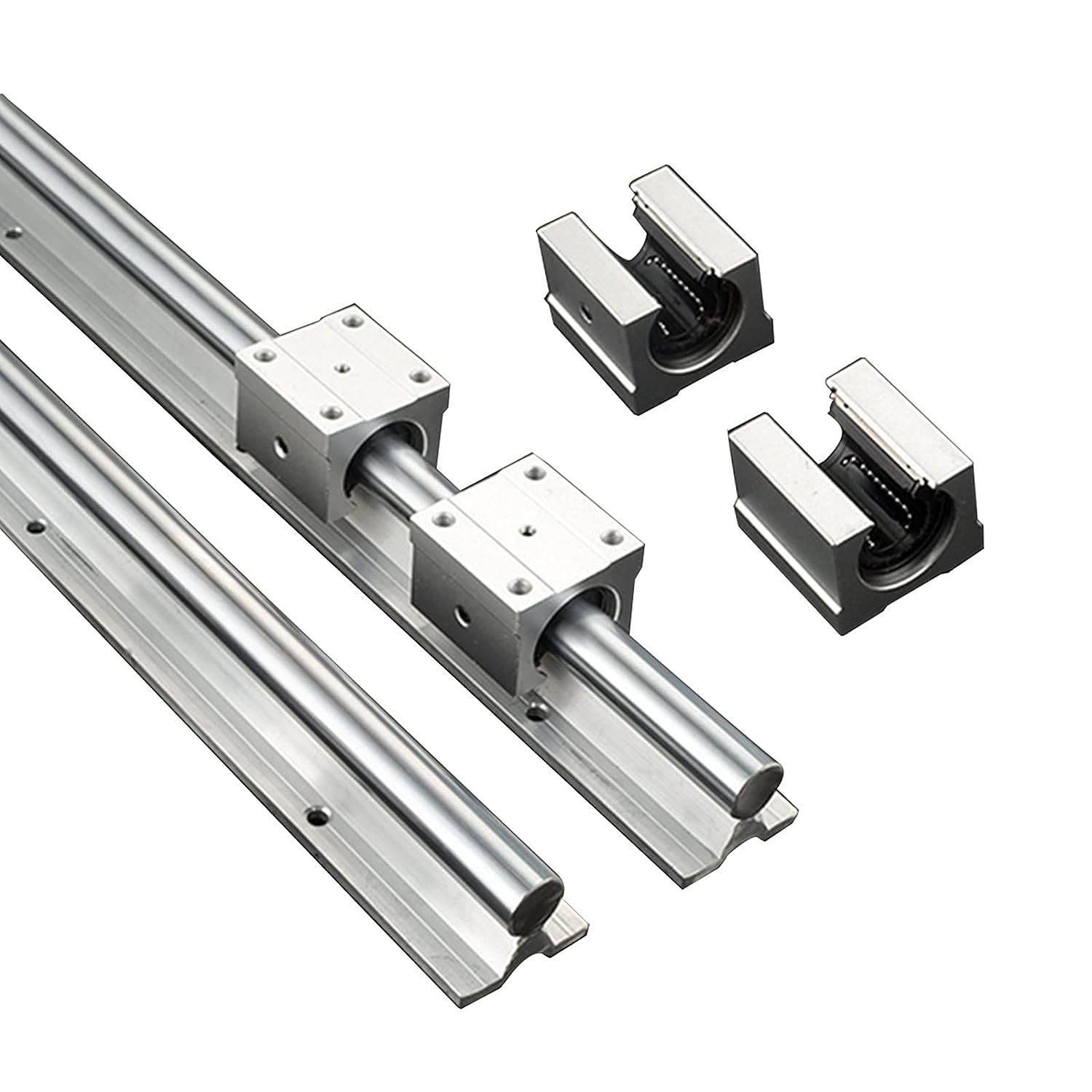

What are linear rails, and how are they used in linear motion systems?

Linear rails, also known as linear guides or linear slides, are mechanical components used in linear motion systems to facilitate smooth and precise movement along a straight path. They typically consist of a rail and a carriage. The rail is a long, rigid structure with a specially designed profile, while the carriage is mounted on the rail and holds the load to be moved.

Linear rails are widely used in various applications, including manufacturing machinery, robotics, 3D printers, and automated systems. They provide guidance and support to the moving components, minimizing friction and ensuring accurate and repeatable motion. The design of linear rails allows for high load-carrying capacity and can accommodate different types of loads, such as radial or axial loads.

Linear motion systems incorporating linear rails offer advantages such as improved precision, reduced wear and tear, and increased efficiency in comparison to traditional sliding mechanisms. The choice of linear rails depends on factors such as load capacity, speed, accuracy requirements, and environmental conditions in the specific application.

editor by Dream 2024-05-17

China Professional High Precision High Quality Interchangeable Linear Rail

Product Description

Product Description

ZCF CHL SERIES – Linear guide of good quality and good accuracy.

Specification

Detailed Photos

Accuracy definition

ACCURACY LEVEL

1. THE ACCURACY OF CH SERIES LINEAR XIHU (WEST LAKE) DIS.S CAN BE DIVIDED INTO FIVE LEVELS: COMMON, HIGH, PRECISION, SUPER-PRECISION AND ULTRA-PRECISION. CUSTOMERS CAN CHOOSE THE ACCURACY LEVEL ACCORDING TO THE ACCURACY REQUIREMENT OF EQUIPMENT.

2. ACCURACY OF NON-INTERCHANGEABLE LINEAR XIHU (WEST LAKE) DIS.:

| MODEL | CH – 15, 20 unit : mm | ||||

| ACCURACY LEVEL | COMMON | HIGH | PRECISION | HIGH-PRECISION | ULTRA-PRECISION |

| (C) | (H) | (P) | (SP) | (UP) | |

| TOLERANCE OF H | ± 0.1 | ± 0.03 | 0- 0.03 | 0- 0.015 | 0- 0.008 |

| TOLERANCE OF N | ± 0.1 | ± 0.03 | 0- 0.03 | 0- 0.015 | 0- 0.008 |

| TOLERANCE OF MUTUAL H | 0.02 | 0.01 | 0.006 | 0.004 | 0.003 |

| TOLERANCE OF MUTUAL N | 0.02 | 0.01 | 0.006 | 0.004 | 0.003 |

| MOTION PARALLELISM OF C ON A | MOTION ACURACY | ||||

| MOTION PARALLELISM OF D ON B | MOTION ACURACY | ||||

| MODEL | CH – 25,30,35 unit : mm | ||||

| ACCURACY LEVEL | COMMON | HIGH | PRECISION | HIGH-PRECISION | ULTRA-PRECISION |

| (C) | (H) | (P) | (SP) | (UP) | |

| TOLERANCE OF H | ± 0.1 | ± 0.04 | 0- 0.04 | 0- 0.02 | 0- 0.01 |

| TOLERANCE OF N | ± 0.1 | ± 0.04 | 0- 0.04 | 0- 0.02 | 0- 0.01 |

| TOLERANCE OF MUTUAL H | 0.02 | 0.015 | 0.007 | 0.005 | 0.003 |

| TOLERANCE OF MUTUAL N | 0.03 | 0.015 | 0.007 | 0.005 | 0.003 |

| MOTION PARALLELISM OF C ON A | MOTION ACURACY | ||||

| MOTION PARALLELISM OF D ON B | MOTION ACURACY | ||||

| MODEL | CH – 45,55 unit : mm | ||||

| ACCURACY LEVEL | COMMON | HIGH | PRECISION | HIGH-PRECISION | ULTRA-PRECISION |

| (C) | (H) | (P) | (SP) | (UP) | |

| TOLERANCE OF H | ± 0.1 | ± 0.05 | 0- 0.05 | 0- 0.03 | 0- 0.02 |

| TOLERANCE OF N | ± 0.1 | ± 0.05 | 0- 0.05 | 0- 0.03 | 0- 0.02 |

| TOLERANCE OF MUTUAL H | 0.03 | 0.015 | 0.007 | 0.005 | 0.003 |

| TOLERANCE OF MUTUAL N | 0.03 | 0.02 | 0.01 | 0.007 | 0.005 |

| MOTION PARALLELISM OF C ON A | MOTION ACURACY | ||||

| MOTION PARALLELISM OF D ON B | MOTION ACURACY | ||||

3. MOTION ACCURACY CHART

| RAIL LENGTH (mm) | ACCURACY LEVEL (µm) | |||||

| C | H | P | SP | UP | ||

| ~ | 100 | 12 | 7 | 3 | 2 | 2 |

| 100 ~ | 200 | 14 | 9 | 4 | 2 | 2 |

| 200 ~ | 300 | 15 | 10 | 5 | 3 | 2 |

| 300 ~ | 500 | 17 | 12 | 6 | 3 | 2 |

| 500 ~ | 700 | 20 | 13 | 7 | 4 | 2 |

| 700 ~ | 900 | 22 | 15 | 8 | 5 | 3 |

| 900 ~ | 1,100 | 24 | 16 | 9 | 6 | 3 |

| 1,100 ~ | 1,500 | 26 | 18 | 11 | 7 | 4 |

| 1,500 ~ | 1,900 | 28 | 20 | 13 | 8 | 4 |

| 1,900 ~ | 2,500 | 31 | 22 | 15 | 10 | 5 |

| 2,500 ~ | 3,100 | 33 | 25 | 18 | 11 | 6 |

| 3,100 ~ | 3,600 | 36 | 27 | 20 | 14 | 7 |

| 3,600 ~ 4,000 | 37 | 28 | 21 | 15 | 7 | |

Production process

Advanced equipments & Rigorous quality control plan

Company Profile

ZheJiang CHINAMFG Precision Technology Co.,Ltd.

is a professional manufacturer of linear guide, linear module and ball screw etc.she is located in HangZhou city,ZheJiang ,China.The production base covers 33333 square CHINAMFG and holds a building area of 16000 square CHINAMFG at present. with over 10 years’ effort of our whole team. and also trust and support from our respected customers. We are so lucky to become 1 famous brand in China, who make international standard products.we aim to serve customers world-widely.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Warehouse Crane, Shipboard Crane, Workshop Crane |

|---|---|

| Material: | Steel |

| Structure: | Machine Table |

| Installation: | All |

| Driven Type: | N/a |

| Carrying Capacity: | Weight Level |

| Samples: |

US$ 20/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are there specific considerations for choosing linear rails in applications with varying environmental conditions or precision requirements?

Yes, specific considerations come into play when choosing linear rails for applications with varying environmental conditions or precision requirements. These considerations ensure that the selected linear rail system is well-suited to the specific challenges and demands of the application. Here are key factors to consider:

Environmental Conditions:

- Temperature: In environments with extreme temperatures, the linear rail materials and coatings must withstand thermal expansion or contraction. High-temperature environments may require materials with enhanced heat resistance, while low-temperature settings may demand materials that remain durable and flexible in cold conditions.

- Corrosion Resistance: For applications in corrosive environments, such as those with exposure to moisture or chemicals, choosing corrosion-resistant materials or coatings is crucial. Stainless steel or specialized coatings can protect against corrosion and extend the lifespan of the linear rail.

- Contaminant Resistance: Environments with dust, debris, or other contaminants require linear rails with effective sealing mechanisms. Sealed or covered linear rail systems prevent the ingress of contaminants, preserving the integrity of the system and ensuring reliable performance.

Precision Requirements:

- Accuracy and Repeatability: Applications demanding high precision, such as in CNC machining or optical systems, require linear rails with superior accuracy and repeatability. Choosing rails with tight tolerances, precision-ground surfaces, and advanced manufacturing processes ensures consistent and reliable linear motion.

- Load Capacity: Precision applications may have stringent load requirements. Selecting linear rails with the appropriate load-bearing capacity ensures that the system can handle the specific loads without compromising precision or accuracy.

- Smooth Operation: Precision linear motion often requires smooth and quiet operation. Rails with anti-friction coatings, self-lubricating properties, or advanced bearing technologies contribute to smooth and silent linear movement, meeting the demands of precision applications.

It’s essential to thoroughly evaluate the environmental conditions and precision requirements of the application before selecting linear rails. Collaborating with experienced suppliers or manufacturers can provide valuable insights and assistance in choosing the most suitable linear rail system that meets the specific challenges posed by varying environmental conditions and precision standards.

How do innovations and advancements in linear rail technology impact their use?

Innovations and advancements in linear rail technology have a profound impact on their use, influencing performance, efficiency, and application possibilities. Here are key ways in which technological advancements impact the use of linear rails:

- 1. Enhanced Precision: Advancements in manufacturing processes and materials contribute to higher precision in the design and production of linear rails. This results in improved accuracy and repeatability in linear motion applications, making them suitable for tasks requiring intricate and precise movements, such as in CNC machining and 3D printing.

- 2. Increased Load Capacities: Ongoing innovations allow for the development of linear rails with increased load-bearing capabilities. This is particularly beneficial in industries and applications where heavy loads need to be moved with precision, such as in industrial automation and material handling systems.

- 3. Integration of Smart Technologies: The integration of smart technologies, such as sensors and feedback systems, enhances the monitoring and control capabilities of linear rail systems. This facilitates real-time data collection, predictive maintenance, and improved overall system efficiency, particularly in automated and Industry 4.0 settings.

- 4. Energy Efficiency: Innovations in lubrication systems and materials contribute to increased energy efficiency in linear rail operation. Reduced friction and optimized designs help minimize energy consumption, making linear rails more environmentally friendly and cost-effective over their lifespan.

- 5. Customization and Modularity: Advanced manufacturing techniques enable greater customization and modularity in linear rail systems. Engineers can tailor linear rails to specific application needs, adjusting parameters such as length, load capacity, and material composition for optimal performance in diverse industrial and automation scenarios.

- 6. Durability and Longevity: Continuous improvements in materials and surface treatments enhance the durability and longevity of linear rails. This is particularly beneficial in applications where reliability and minimal maintenance are critical, such as in aerospace testing equipment and high-precision manufacturing.

Overall, innovations in linear rail technology contribute to a broader range of applications, improved performance metrics, and the ability to meet the evolving needs of diverse industries. As technology continues to advance, the versatility and effectiveness of linear rails in various industrial and automation settings are likely to expand even further.

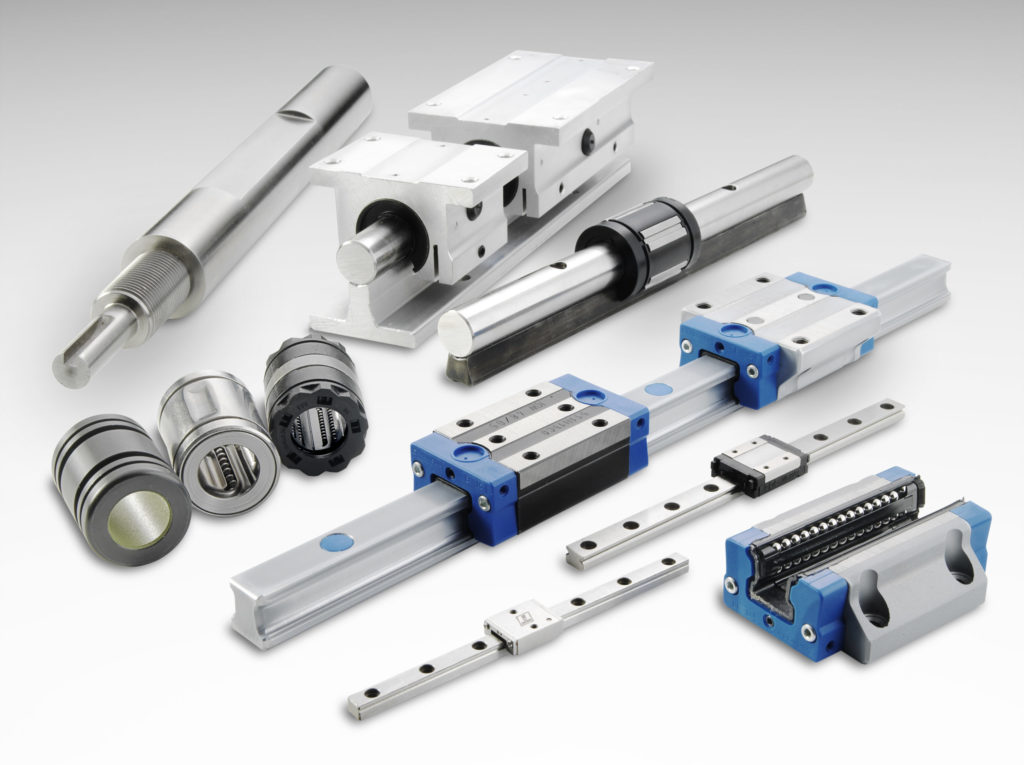

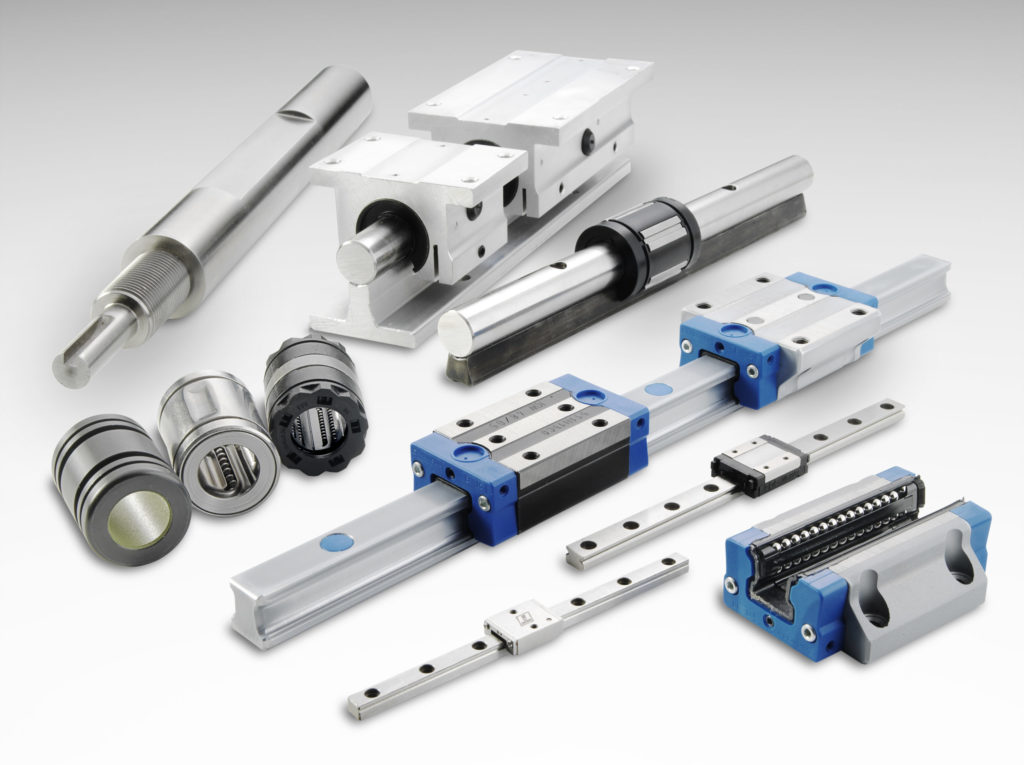

How do linear rails differ from other linear motion components like linear guides or bearings?

While linear rails, linear guides, and bearings are all components used in linear motion systems, they differ in their design, functions, and applications:

Linear Rails: Linear rails typically consist of a long, rigid rail and a carriage that moves along the rail. The rail has a specially designed profile to provide guidance, and the carriage supports and carries the load. Linear rails are known for their ability to handle high loads, offer precise linear motion, and reduce friction for smooth movement.

Linear Guides: Linear guides encompass a broader category that includes linear rails. Linear guides refer to any mechanism that guides linear motion. Linear rails are a specific type of linear guide with a distinctive profile. Linear guides, in a general sense, can include other mechanisms like dovetail slides, boxway guides, and more, each with its own design and application.

Bearings: Bearings are components that reduce friction between moving parts and support radial or axial loads. While linear rails may incorporate bearings within their design, bearings, in a broader sense, can be standalone components used to support rotating or linear motion. Linear bearings, for example, specifically support linear motion and may be used independently or as part of a linear rail system.

In summary, linear rails are a specific type of linear guide with a defined rail and carriage design, whereas linear guides encompass a broader category. Bearings, on the other hand, are components that reduce friction and support loads, and linear bearings specifically cater to linear motion.

editor by Dream 2024-05-17

China Best Sales CZPT Hgw15 Hgw20 Hgw25 CNC Linear Guide Rail Linear Guide Slider Block 1000mm 2000mm linear rail bearing

Product Description

CZPT HGW15 HGW20 HGW25 CNC Linear Xihu (West Lake) Dis. Rail Linear Xihu (West Lake) Dis. Slider Block 1000mm 2000mm

Product Description

Specification:

|

Product Name |

Linear guide |

|

Material |

Bearing steel, Gcr15 |

|

Precision |

C, H, P |

|

Width |

15mm-45mm |

|

Length |

100mm-4000mm |

|

Advantage |

High precision, high speed, long life, high reliability, low noise |

|

Packing |

Plastic bag + wooden box or according to customers’ demands |

Packaging & Shipping

Packaging Details:

1)Sample order packing by paper carton for saving freight charge;

2)bulk order sent by sea will be packed by film and wooden carton.

3) as customer’s requirements.

Company Profile

Company Information:

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd is located at Xihu (West Lake) Dis. industrial zone Xihu (West Lake) Dis. County which is the beautiful Xihu (West Lake) Dis.

Water City and the famous painting and calligraphy village.The south is national road 308, the west is the national highway 105,

the north is HangZhou-HangZhou highway, so the position is very superior. It is 1 of the biggest linear manufacturers in China.

Certifications

FAQ

1. Q: How about the quality of your product?

A: 100% inspection during production.

Our products are certified to ISO9001-2008 international quality standards.

2. Q: What’s the delivery time?

A: For custom order, within 2000 meters,

Production time is 15days after confirmed every details.

3. Q: What’s your packing?

A: Our Normal packing is bulking in PE bag, and then into plywood Cartons.

We also can pack products according to your requirement.

4. Q: What about the warranty?

A: We are very confident in our products,

and we pack them very well to make sure the goods in well protection.

5.Q: Could you send me your catalogue and price list?

A: As we have more than hundreds of products,

it is really too hard to send all of catalogue and price list for you.

Please inform us the style you interested, we can offer the pricelist for your reference.

6.Q:There are a lot of companies which export bearings, why do you choose us?

A: As we are a genuine linear guide supplier since 2011.and we are really factory, you need not pay the profit for middlemen.

so we can offer you the lowest and competitive price .

Thanks for your valuable time !

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | CNC Machine Parts |

|---|---|

| Material: | Gcr15 Bearing Steel |

| Structure: | Linear Guide Rail |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Using a “Traditional” Linear Rail in a 3D Printer Build

Using a “traditional” linear rail in a 3D printer build is a great way to add a bit of extra strength to your printer’s frame, but it comes with a few drawbacks. The following article will explain some of the reasons you might want to consider a sliding carriage and rail instead.

Applications

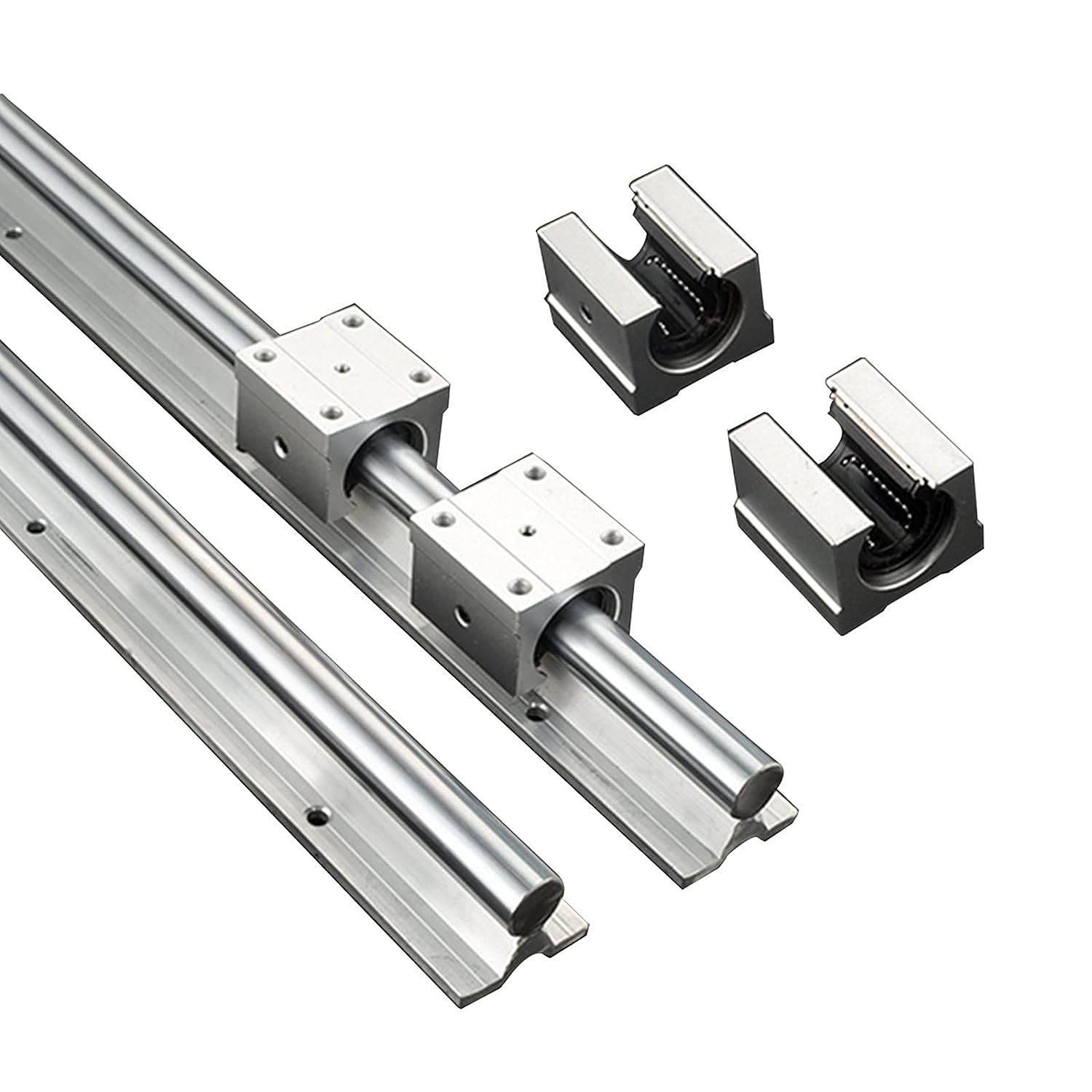

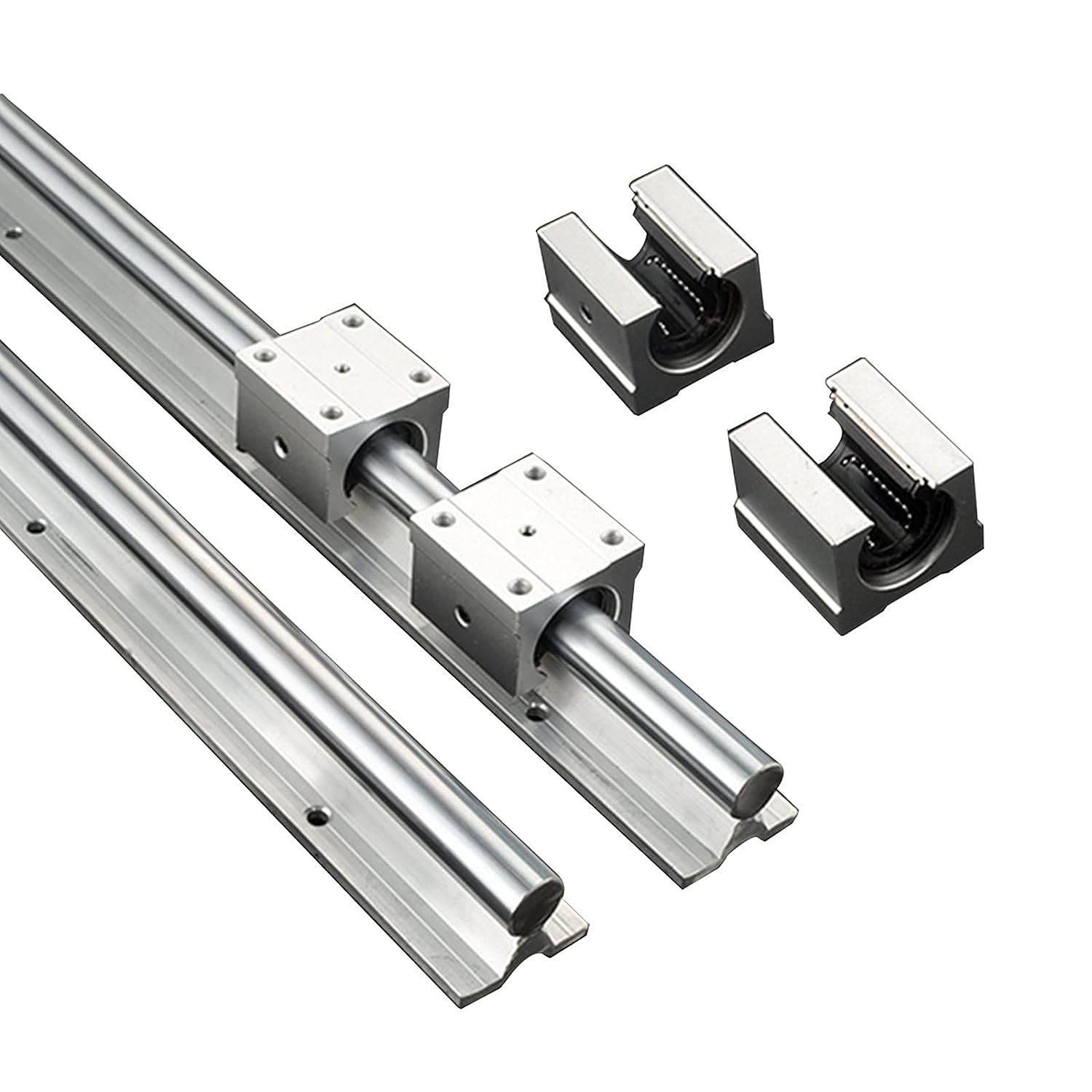

Basically, a Linear Rail System is a piece of mechanical equipment designed to sustain the motion of equipment. The system uses a combination of linear guides and bearings to maintain a steady motion.

The linear rail system is used in many industries, from manufacturing to transportation. It is important to design the system to suit the intended application. Some of the most common applications include material transfer, medical sample handling and factory automation.

The most common type of linear rail is the recirculating ball guide. Recirculating ball guides offer many advantages, including moment control, high load capacity and precision. However, there are limitations in some applications.

In the food and beverage industry, special linear bearings are necessary to handle harsh conditions and to meet health and safety standards. Some applications include weighing machines, pick and place modules, and packaging systems.

Linear rails also require precision mounting surfaces to ensure accurate motion. They are available in various lengths and are suitable for most applications.

A linear rail system can be used horizontally or vertically. They provide a smooth motion, reducing friction and minimizing wear. Linear Rail Systems can support loads ranging from a few grams to thousands of kilograms. The rail itself is made from high-strength steel and can be galvanised for added durability.

Linear Rail Systems can be used in a wide variety of industries, from pharmaceutical manufacturing to semiconductor manufacturing. The systems are easy to install and have a heavy load bearing capacity. They provide high stiffness and load capacity, and are perfect for moving loads with minimal friction. These systems also have low frictional resistance, which is important in pneumatic-driven systems.

There are several other advantages to using linear rails, including low cost, high load capacity, low friction and low maintenance. The rails are made from stainless steel or carbon steel.

CZPT linear guide rails

CZPT has a full lineup of linear guide rails, slides, and carriages to suit almost any application. Whether you’re assembling a high tech medical instrumentation system or automating your garage, CZPT has the equipment to get the job done. The company offers a wide selection of linear motion equipment ranging from mountable linear bearings to miniature guide rail and carriage assemblies.

The company also offers a full range of linear guide rails and carriages from high strength steel to high tech aluminum. The company’s extensive selection of linear motion products can be accessed through its convenient online ordering system. It also has a number of useful guides to help you choose the best equipment for your needs.

CZPT’s line of linear guide rails and carriages also includes space saving miniature guide rail and carriage assemblies. With a product lineup boasting over 500 linear motion devices, the company has something for just about every budget and need. CZPT’s line of linear guide systems is engineered to ensure maximum efficiency and reliability in an array of applications. CZPT’s linear guide products are the best in the industry. A CZPT linear guide can stand up to tearing loads and torque forces. Its superior performance can be maintained in a clean environment with proper maintenance. A well maintained rail can last for many years.

CZPT has a number of eminently sexy linear guide and carriage solutions to suit any application. You can browse by manufacturer or category to find what you’re looking for. From drilled and undrilled linear rails to carriages to linear guide slides, CZPT can help you make your next project a success. The company offers the best prices in the business and its products are made in the United States and Canada.

Sliding carriage and rail

Whether you’re looking for a new or used linear carriage and rail, there are a few things to keep in mind. For instance, you’ll need to choose a sturdy base material, like granite or steel, that can withstand the weight of the load. In addition, you’ll need to secure the linear components to the base.

Also, you’ll need a control system to regulate the carriage’s motion. These systems can be controlled by operator controls or feedback signals from sensors. If your application calls for a heavy load, you might want to consider a profiled rail.

Another option is a sleeve bearing slide. These slides are designed to be simple to operate, but they are not as durable as other slides.

A sleeve bearing slide is typically used in light-weight applications. It can be made of a variety of materials, including aluminum, steel, or stainless steel. These slides can have a ball screw drive and a linear motor.

These slides can also have rolling element bearings. These balls are used to support the load in the carriage. This decreases friction and provides a smoother motion.

In addition, these slides can be lubricated. You can find these slides in a variety of designs, including recirculating and non-recirculating. In non-recirculating designs, the rolling elements travel at half the speed of the carriage. In recirculating designs, the rolling elements follow the carriage’s looped course.

Some linear guides offer a variety of materials, including stainless steel, aluminum, and granite. These materials can be customized to match your needs. Some may also have custom-engineered features, such as a rail and bearing system, stage, and drive units. If you’re looking for a cost-effective solution, you may want to consider a custom-engineered linear slide.

Robot transport units

Adding linear movement to a Robot system is an effective way to enhance a Robot’s performance. The robot can now move larger and heavier workpieces to and from different machines, and to increase its utility. Adding linear movement also increases the number of activities that can be performed. This increases the robot’s throughput and helps to maximize the return on investment.

The Robot Transfer Unit (RTU) is an effective solution for adding linear movement to Robot systems. It increases the efficiency of 6-axis robots by allowing them to move workpieces along a moving conveyor line. RTUs are used in material handling applications such as welding, painting, inspection, and palletizing.

Robot Transfer Units can be floor-mounted, or raised above operations or the floor. This increases worker freedom of movement, while allowing for improved access to machinery by maintenance personnel. They also save floor space and can allow materials to be moved closer to the work area.

RTUs are used to carry robots between work stations and in material-handling applications. They are generally floor-mounted or can be elevated to save floor space and provide a view of the operation.

A typical RTU will include two workpiece transport units. Each workpiece transport unit includes a robotic arm, a guide rail, and a slidably mounted arm. Each workpiece transport unit also includes an electromagnet that propels the unit along the guide rail. The arm can rotate or “flip” about a horizontal axis (R) and the end effector can hold wafers (W) or rotate about a vertical axis (Z 2).

Each transport unit has a lateral outside dimension 640. This allows the unit to be slidably mounted on both sides of the guide rail structure.

Drawbacks of using “traditional” linear rail in a 3D printer build

Using a traditional linear rail in a 3D printer build isn’t for the faint of heart. If you’re building a printer for your own personal use, it’s likely you’ll have to do a bit of tinkering to get the machine working as it should. Luckily, there are many alternatives to the conventional build process. For example, you can build a machine with an aluminum extrusion instead of using the traditional molten plastic. This allows you to print a wider range of materials and improves the machine’s longevity. Alternatively, you could use an aluminum extrusion with a delrin wheel for improved print quality.

You could also build a 3D printer from scratch with a custom frame made from aluminum. The material is a good choice if you’re looking to print large format items. The material is also lightweight, which translates into improved print quality and a smoother print experience. Using an aluminum extrusion for the frame of a 3D printer could save you some serious cash, if you know what you’re doing.

It’s a good idea to do your homework before making a purchase. The best way to avoid getting ripped off is to find a reputable manufacturer and check the credentials of the company’s products. This is especially true if you’re looking to buy a machine that can be used to build 3D models of your own designs. As with anything, buying the wrong printer for the wrong application can lead to disaster. Thankfully, you can avoid some of the pitfalls with a little research and a few recommendations. If you’re looking to build the machine of your dreams, take the time to learn what you’re doing first.

editor by Dream 2024-05-16

China Custom Black High Precision Linear Guide Automatic Machine Repair Spare Parts linear rail and bearings

Product Description

High Precision EGW15CC CZPT Linear Block Slide Linear Xihu (West Lake) Dis. Rail for packing machine

| Brand | TOCO |

| Model | EGH15CA,EGH20CA,EGH25CA, |

| Size customize | 15,20,25,30,35 |

| Style | With Flange or not ,butt Joint Process. |

| HS CODE | 8483900090 |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T,Western Union |

| Production lead time | 5~7 days for sample , 15~30 days for the bulk |

| Samples | Sample price range from $50 to $200. sample express request pay by clients |

| Application | CNC machines, Printing Machine ,Paper-processing machine Machine tool, Solar energy equipment, Medical equipment, General industry machinery. Parking system |

Features

1.High positioning accuracy, high repeatability

The linear guideway is a design of rolling motion with a low friction coeffi cient, and the diff erence between dynamic and static friction is very small. Therefore, the stick-slip will not occur when submicron feeding is making.

2.Low frictional resistance, high precision maintained for long period

The frictional resistance of a linear guideway is only 1/20th to 1/40th of that in a slide guide. With a linear guideway, a well lubrication can be easily achieved by supplying grease through the grease nipple on carriage or utilizing a centralized oil pumping system, thus the frictional resistance is decreased and the accuracy could be maintained for long period.

3.Suitable for high speed operation

Due to the characteristic of low frictional resistance, the required driving force is much lower than in other systems, thus the power consumption is small. Moreover, the temperature rising effect is small even under high speed operation.

4.Easy installation with interchangeability

Compared with the high-skill required scrapping process of conventional slide guide, the linear guideway can offer high precision even if the mounting surface is machined by milling or grinding. Moreover the interchangeability of linear guideway gives a convenience for installation and future maintenance.

Company

If you’re looking for linear guide ,transmission parts supply or service, you need someone you can trust, someone who appreciates how critical those parts are to your business and knows exactly what is required to keep you up and running smoothly and efficiently.

We at CZPT transmission Co.,Ltd. can offer unrivalled product and application knowledge, we can supply ballscrew products of any size or type to our valued customer.

We place huge importance on our reputation – a reputation that seems to preceed us more and more. This reputation can only grow through good service and quality products so we’re committed to expanding our range with nothing but the best products and services and the in-house knowledge to back it all up. Of course, in-house knowledge is vitally important, not just to us, but you as a customer – so we’re proud to host some of the best people in the industry.

We are the ballscrew supplier you can trust.

FAQ

1. Service :

a. Help customer to choose correct model

b. Professional sales team, make your purchase smooth.

2.payment :

Sample order: We require 100% T/T in advance. sample express need request pay by clients

Bulk order: 30% T/T in advance, balance by T/T against copy of B/L.

T/T,Paypal, Western Union is acceptable.

3.Delievery :

sample: 5-10 business days after payment confirmed.

Bulk order :10-20 workdays after deposit received .

4. Guarantee time

TOCO provides 1 year quality guarantee for the products from your purchase date, except the artificial damage.

5.After sale-service

During warranty period, any quality problem of CZPT product, once confirmed, we will send a new 1 to replace.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | Anti-Static, Cold-Resistant, Corrosion-Resistant, Linear Guide |

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Electric Cars, Food Machinery, Mining Equipment, Agricultural Machinery, Transmission and Guidancetransmission and Guidance |

| Surface Treatment: | Chrome Plating |

| Material: | Carbon Steel |

| Stocks: | Rich |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Sliding Contact Guide on Linear Rail

Whether it is a dovetail, sliding contact guide, sleeve-bearing slide, or box way rails, we’re going to look at some of the options available to you. You’ll learn about what they do, how they can help you, and how they can improve your work.

Dovetail rails

Several varieties of dovetail rails are available in the market. Among them are the standard boxway rails and a more specialized variant. These rails are known for their sleek and sturdy appearance and can handle even heavier loads than their counterparts.

The DS Series Compact Dovetail Linear Stages are the smallest of the lot, yet feature the same mechanism as the MT series dovetail stages. They slide along precision preloaded dovetail slides, making them a good choice for applications that require high performance, but limited space. These stages are also less prone to shock than their conventional counterparts.

The DS series dovetail stages are available in a variety of XYZ configurations, making them ideal for applications requiring the smoothest of motions and the least amount of vibration. These stages are also easy to integrate into your system thanks to their modular design. This is especially true in the case of the DS25 series, which has a lower footprint than the MT series.

The DS Series Compact Dovetail Stages are a step up from the MT series dovetail stages. This is thanks to their high-speed, precision preloaded dovetail slides. These are not only lightweight, but also silent, which is particularly useful in medical applications. These stages feature the aforementioned low-profile design, as well as thicker and more robust saddles. They are also available in two different travel ranges.

While dovetail rails on linear rails may be a good choice for your next project, you should consider some of the factors that can shorten its life. Some of the most common failures are abrasions, corrosion, and dust. You may also want to consider a platform to attach to your system’s moving component. This can allow you to increase the size of the transport area, while still keeping your load close at hand.

The DS Series Compact Dovetail line of dovetail stages are a good choice for applications that require the smoothest of motions and the least number of components. This is especially true in the case of DS series dovetail stages, which do not use typical roller bearings.

Sleeve-bearing slides

Depending on the application, there are different types of linear rail slides. The most common is the ball bearing slide, which uses two linear rows of ball bearings to move a carriage. The design offers smooth motion in a single direction.

Another type of slide is the dovetail slide. It involves a slot on the base of the slide and a protruding V-shaped tongue on the saddle. This design is more durable than other slides, and can be used for heavy load applications. However, it can’t handle as large a load as boxway slides, which involve a mating base and saddle.

A third type of slide is the cylindrical column slide. It is functionally similar to the square gib slide, but lacks the strength and stiffness of the latter. It’s usually more expensive and harder to assemble, although it offers a more accurate form of mechanical linear motion.

The inner surface of a linear sleeve bearing is usually made up of a journal slide. It’s a common way to reduce friction through surface coating. Some of these slides are made from CZPT, a material that’s inert to acids and solvents. It’s also designed to work in varying environments.

There are several types of bushings, and each can be made from a wide range of alloys. Bronze bushings are designed for a smooth motion, while plastic bushings are suited for low-speed applications.

For applications requiring high-speed operation, linear sleeve bearings can be manufactured in ceramic rolling elements. These offer less noise and better distribution of load.

Another type of linear rail slide is the box-way slide. It includes a mating base and saddle. It’s often used for heavy-duty applications. A third section can be attached to the saddle, extending the length of the slide. These slides offer a T-shaped profile when fitted.

The square gib design is an excellent choice for heavy-duty applications. It offers accurate linear movement and high load capacity. It can be milled, drilled, or tapped. It has low friction, and can withstand force in any direction.

The CZPT design has excellent performance in both smooth and harsh environments. It’s also long, making it ideal for large installations.

Sliding contact guides

Choosing a sliding contact guide on linear rail can be tricky. With a variety of options available, it’s important to understand the differences between them and the advantages they provide.

The first of these is the material used. Stainless steel, aluminum, or cast iron are common materials for sliding guides. These materials are durable and will withstand heavy loads. They can also be used in corrosive environments.

The other important factor is the lubrication method. The amount of lubrication required is largely determined by the type of linear slide and the type of bearings it uses. Ball bearing slides typically need less lubrication than linear bearing slides. The lubrication method is also important because it reduces the friction that leads to wear.

The most important thing about the lubrication method is that it should be easy to access and clean. This can ensure that you get the best performance out of your linear guide. You may also choose to upgrade the lubrication to increase the lifetime of your guide.

Another important factor is the size of the application. A larger capacity will allow the guide to carry a heavier load. You can also choose a higher speed guide if the application involves high speeds. The length of the guide should also be considered. The length is usually dictated by the size of the application. You can also customize the length of your guide by contacting your nearest sales office.

The biggest difference between sliding contact guides on linear rail and other linear guides is the amount of friction. The more force you apply, the higher the coefficient of friction will be. Therefore, this type of guide is not suitable for high speed applications.

The first recirculation ball was developed by Thomson Linear. This was the first commercialized rolling element. The ball has a much lower coefficient of friction than a roller. This is why it is often used in motion control applications.

A high speed operation will require more lubrication than a low speed operation. The E-DFO coating of the lubricant reportedly has a longer life than fluororesin coating.

Box way rails

Unlike the conventional linear guideways which consist of a thin film of lubricating oil between them, the box way rails run under sliding friction. The box way systems are made of a tough material, such as steel. They are capable of handling heavier loads than the dovetail rails. They are also better at absorbing shock loads. However, their service life is shorter than that of linear rails. The linear guideway VMCs are often two or three times faster than the boxy counterparts.

The most common material used in linear guideways is steel. It is usually manufactured with high precision. It is then graded for a specific application. The bearing plates have smooth transitions and can carry increasing loads as they become convex. This design makes it ideal for machining steel.

While the linear rail has a higher carrying capacity, the box way system is still relatively small. The box ways can handle higher loads than dovetail rails. However, they cannot handle a high running speed. They are also considered to be better at reducing chatter.

The main components of a linear slide are the main carriage and bearings. They incorporate power screws and ball bearings. The main difference between the two is that the ball bearings have rolling elements that can reduce friction. The rolling element bearings also have high sensitivity. The friction between the rolling element and the rail is also low.

Box ways also have a better vibration dampening capability. However, they are not ideal for consumer applications. They are also much more expensive than the linear guideways. The cost is offset by the fact that they require less maintenance. It is therefore recommended that box way systems are used in heavy-duty applications.

Linear rails are a convenient alternative to box-way rails. However, they must be fully supported in assembly. They also require more lubrication. In addition, they can be damaged by water and other solvents. They also need to be protected during shipment.

Box ways are used in some larger machines, while the linear slides are used in smaller machines. These types of rails are generally used by machining centers that make part products. They can also be used in roughing machine tools.

editor by Dream 2024-05-16

China Good quality China Factory Direct P/Sp Level Linear Slide Guide Rail

Product Description

Product Description

ZCF BRIEF INTRODUCTION:

ZCF PRECISION TECHNOLOGY(HangZhou) CO.,LTD. IS A PROFESSIONAL MANUFACTURER OFLINEARXIHU (WEST LAKE) DIS.,LINEAR MODULE AND BALL SCREW ETC.SHE IS LOCATED IN HangZhou CITY,ZheJiang ,CHINA.THE NEW FACTORY COVERS 33333 SQUARE CHINAMFG AND HOLDS A BUILDING AREA OF 16000 SQUARE CHINAMFG AT PRESENT. WITH OVER 10 YEARS’ EFFORT OF OUR WHOLE TEAM. AND ALSO TRUST AND SUPPORT FROM OUR RESPECTED CUSTOMERS. WE ARE SO LUCKY TO BECOME ONE STRONG BRAND IN CHINA, WHO MAKE INTERNATIONAL STHangZhouRD PRODUCTS.WE AIM SERVE CUSTOMERS WORLDWIDELY.

PRODUCTS PHOTOS:

CH SERIES BODY STRUCTURE:

1.ROLLING CYCLE SYSTEM: SLIDER, XIHU (WEST LAKE) DIS. RAIL, END COVER, STEEL BALL, BALL HOLDER;

2.LUBRICATION SYSTEM: OIL NOZZLE AND TUBING JOINT

3.DUST-PROOF SYSTEM: OIL SCRAPER, NEGATIVE DUST SEAL DUST-PROOF SHEET, XIHU (WEST LAKE) DIS. RAIL BOLT COVER, METAL SCRAPER

ACCURACY LEVEL

1. THE ACCURACY OF CH SERIES LINEAR XIHU (WEST LAKE) DIS.S CAN BE DIVIDED INTO FIVE LEVELS: COMMON, HIGH, PRECISION, SUPER-PRECISION AND ULTRA-PRECISION. CUSTOMERS CAN CHOOSE THE ACCURACY LEVEL ACCORDING TO THE ACCURACY REQUIREMENT OF EQUIPMENT.

2. ACCURACY OF NON-INTERCHANGEABLE LINEAR XIHU (WEST LAKE) DIS.:

| MODEL | CH – 15, 20 unit : mm | ||||

| ACCURACY LEVEL | COMMON | HIGH | PRECISION | HIGH-PRECISION | ULTRA-PRECISION |

| (C) | (H) | (P) | (SP) | (UP) | |

| TOLERANCE OF H | ± 0.1 | ± 0.03 | 0- 0.03 | 0- 0.015 | 0- 0.008 |

| TOLERANCE OF N | ± 0.1 | ± 0.03 | 0- 0.03 | 0- 0.015 | 0- 0.008 |

| TOLERANCE OF MUTUAL H | 0.02 | 0.01 | 0.006 | 0.004 | 0.003 |

| TOLERANCE OF MUTUAL N | 0.02 | 0.01 | 0.006 | 0.004 | 0.003 |

| MOTION PARALLELISM OF C ON A | MOTION ACURACY | ||||

| MOTION PARALLELISM OF D ON B | MOTION ACURACY | ||||

3. MOTION ACCURACY CHART

| RAIL LENGTH (mm) | ACCURACY LEVEL (µm) | |||||

| C | H | P | SP | UP | ||

| ~ | 100 | 12 | 7 | 3 | 2 | 2 |

| 100 ~ | 200 | 14 | 9 | 4 | 2 | 2 |

| 200 ~ | 300 | 15 | 10 | 5 | 3 | 2 |

| 300 ~ | 500 | 17 | 12 | 6 | 3 | 2 |

| 500 ~ | 700 | 20 | 13 | 7 | 4 | 2 |

| 700 ~ | 900 | 22 | 15 | 8 | 5 | 3 |

| 900 ~ | 1,100 | 24 | 16 | 9 | 6 | 3 |

| 1,100 ~ | 1,500 | 26 | 18 | 11 | 7 | 4 |

| 1,500 ~ | 1,900 | 28 | 20 | 13 | 8 | 4 |

| 1,900 ~ | 2,500 | 31 | 22 | 15 | 10 | 5 |

| 2,500 ~ | 3,100 | 33 | 25 | 18 | 11 | 6 |

| 3,100 ~ | 3,600 | 36 | 27 | 20 | 14 | 7 |

| 3,600 ~ 4,000 | 37 | 28 | 21 | 15 | 7 | |

SELECTION CRITERIA

1. PRODUCT APPLICATIONS:

1). CH SERIES: GRINDING MACHINE, MILLING MACHINE, LATHE, DRILLING MACHINE, INTEGRATED PROCESSING MACHINE, EDM MACHINE, BORING MACHINE, WIRE CUTTING MACHINE, PRECISION

2). CE SERIES: INDUSTRIAL AUTOMATION MACHINERY, SEMICONDUCTOR MACHINERY, LASER ENGRAVING MACHINE, PACKAGING MACHINE;

3). CGN/CGW SERIES: PRINTER, MACHINE ARM, ELECTRONIC INSTRUMENT AND SEMICONDUCTOR EQUIPMENT.

2. SELECTION OF ACCURACY LEVEL:

C, H, P, SP, UP LEVELS DEPEND ON EQUIPMENT ACCURACY REQUIREMENTS.

3. SELECTION OF SIZE:

1). ACCORDING TO EXPERIENCE;

2). LOAD STATUS;

3). IF LINEAR XIHU (WEST LAKE) DIS.WAY IS USED IN CONJUNCTION WITH BALL SCREW, SELECT SIMILAR SIZE AS EXTERNAL DIAMETER OF THE SCREW. IF THE EXTERNAL DIAMETER OF THE SCREW IS 35 MM, SELECT CH35.

4. CALCULATING THE MAXIMUM LOAD OF SLIDER:

1). CALCULATING THE MAXIMUM EQUIVALENT LOAD OF A SINGLE SLIDER WITH REFERENCE TO THE LOAD CALCULATION TABLE

2). CONFIRMATION THAT THE STATIC SAFETY FACTOR OF THE SELECTED STRAIGHT-LINE XIHU (WEST LAKE) DIS. SHOULD EXCEED THE VALUE LISTED IN THE TABLE OF STATIC SAFETY FACTOR

LUBRICATION:

IF THE LINEAR XIHU (WEST LAKE) DIS. IS NOT PROPERLY LUBRICATED, THE FRICTION OF ROLLING PARTS WILL INCREASE, AND LONG-TERM USE WILL BECOME THE MAIN REASON FOR SHORTENING THE LIFE. LUBRICANTS PROVIDE THE FOLLOWING FUNCTIONS:

(1). REDUCE FRICTION OF ROLLING PARTS, PREVENT BURNS AND REDUCE WEAR;

(2). FORMING OIL FILM BETWEEN ROLLING SURFACE AND ROLLING SURFACE CAN PROLONG ROLLING FATIGUE LIFE;

(3). PREVENTING RUST.

1. GREASE LUBRICATION:

EACH GROUP OF LINEAR XIHU (WEST LAKE) DIS.WAYS CAN BE SEALED WITH LITHIUM SOAP-BASED GREASE TO LUBRICATE THE BEAD GROOVE TRACK BEFORE LEAVING THE FACTORY. ALTHOUGH THE GREASE IS NOT EASY TO LOSE, IN ORDER TO AVOID INSUFFICIENT LUBRICATION CAUSED BY LUBRICATION LOSS, IT IS SUGGESTED THAT CUSTOMERS SHOULD SUPPLEMENT THE GREASE ONCE MORE WHEN THE DISTANCE REACHES 100 KM. AT THIS TIME, GREASE CAN BE INJECTED INTO THE SLIDER BY MEANS OF THE OIL NOZZLE ATTACHED TO THE SLIDER. LUBRICATING GREASE IS SUITABLE FOR SITUATIONS WHERE THE SPEED IS NOT MORE THAN 60 M/MIN AND THE COOLING EFFECT IS NOT REQUIRED.

T : OIL INJECTION FREQUENCY (hour); Ve : SPEED (m/min)

2. OIL (OIL) LUBRICATION:

IT IS RECOMMENDED THAT CUSTOMERS USE LUBRICATING OIL WITH A CONSISTENCY OF ABOUT 32-150 CHINAMFG TO LUBRICATE LINEAR XIHU (WEST LAKE) DIS.S. CHINAMFG CAN INSTALL THE TUBING JOINT AT THE ORIGINAL POSITION OF THE OIL DISCHARGE NOZZLE ACCORDING TO THE CUSTOMER’S NEEDS, SO THE CUSTOMER ONLY NEEDS TO CONNECT THE PRESET TUBING OF THE MACHINE TO THE TUBING JOINT. THE LOSS OF LUBRICATING OIL IS FASTER THAN THAT OF LUBRICATING GREASE. WHEN USING, ATTENTION MUST BE PAID TO THE ADEQUACY OF OIL SUPPLY. IF INSUFFICIENT LUBRICATION EASILY CAUSES ABNORMAL WEAR OF LINEAR XIHU (WEST LAKE) DIS.S AND REDUCES THEIR SERVICE LIFE, IT IS SUGGESTED THAT THE FREQUENCY OF LUBRICATING OIL SHOULD BE ABOUT 0.3CM3/HR. CUSTOMERS CAN USE IT ACCORDING TO THEIR USE CONDITIONS. LUBRICATING OIL IS SUITABLE FOR VARIOUS LOADS AND SPEEDS, BUT IT IS NOT SUITABLE FOR HIGH TEMPERATURE LUBRICATION BECAUSE OF ITS VOLATILITY.

DUST-PROOF DEVICE(OPTIONS)

1. DUST-PROOF DEVICE CODE:

IF YOU NEED THE FOLLOWING DUST-PROOF EQUIPMENT, PLEASE ADD THE CODE AFTER THE PRODUCT MODEL.

INSTALLATION OF LINEAR XIHU (WEST LAKE) DIS.WAY

THE INSTALLATION METHOD OF LINEAR XIHU (WEST LAKE) DIS. MUST BE SET ACCORDING TO THE OPERATING CONDITION OF THE MACHINE, SUCH AS THE DEGREE OF VIBRATION AND IMPACT FORCE, THE REQUIRED WALKING ACCURACY AND THE LIMITATION OF THE MACHINE.WHEN PAIRING NON-INTERCHANGEABLE LINEAR XIHU (WEST LAKE) DIS.S, ATTENTION SHOULD BE PAID TO THE DIFFERENCE BETWEEN THE REFERENCE RAIL AND THE DRIVEN RAIL. THE ACCURACY OF THE DATUM LEVEL ON THE SIDE OF THE DATUM RAIL IS HIGHER THAN THAT OF THE DRIVEN RAIL, SO IT CAN BE USED AS THE SUPPORTING SURFACE FOR THE BED INSTALLATION. THE REFERENCE RAIL IS MARKED WITH MA, AS SHOWN IN THE FIGURE.

1. FIXING METHODS

WHEN THE BED IS SUBJECTED TO VIBRATION AND IMPACT FORCE, THE XIHU (WEST LAKE) DIS. RAIL AND SLIDER MAY DEVIATE FROM THE ORIGINAL FIXED POSITION AND AFFECT THE ACCURACY. IN ORDER TO AVOID SIMILAR SITUATION, IT IS SUGGESTED TO USE THE FOUR FIXED WAYS LISTED BELOW TO FIX THE XIHU (WEST LAKE) DIS. RAIL AND SLIDER TO ENSURE THE ACCURACY OF THE MACHINE.

2. INSTALLATION OF LINEAR RAIL:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machine Parts |

|---|---|

| Material: | Steel |

| Structure: | Machine Parts |

| Installation: | All-Terrain Crane |

| Driven Type: | N/a |

| Carrying Capacity: | Weight Level |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide guidance on the selection and sizing of linear rails for specific linear motion applications?

When selecting and sizing linear rails for specific linear motion applications, several factors need to be considered to ensure optimal performance. Here is guidance on the key considerations:

1. Load Requirements: Determine the maximum load the linear rail system will need to support. Consider both static and dynamic loads, as well as any potential impact or shock loads during operation.

2. Travel Distance: Evaluate the required travel distance of the linear rail system. Different rail types and designs are suitable for short-range, medium-range, or long-range travel, so choose accordingly based on the application’s needs.

3. Precision and Accuracy: Assess the precision and accuracy requirements of the application. High-precision applications, such as CNC machining or optical systems, may require linear rails with specialized designs to meet stringent accuracy standards.

4. Speed and Acceleration: Consider the desired speed and acceleration of the linear motion. Different rail systems have specific capabilities in terms of speed and acceleration, so choose a system that aligns with the application’s performance requirements.

5. Environmental Conditions: Evaluate the environmental conditions in which the linear rail will operate. Factors such as temperature, humidity, and exposure to contaminants can impact the choice of materials, coatings, and lubrication for the linear rail system.

6. Mounting Configurations: Consider the available space and mounting configurations in the application. Linear rails come in various designs, including profiled rail systems, round rail systems, and others. Choose a design that fits the available space and allows for easy integration.

7. Budget Constraints: Assess budget constraints and cost considerations. Linear rail systems come in a range of price points, and balancing performance requirements with budget constraints is essential for cost-effective solutions.

8. Manufacturer and Supplier Expertise: Collaborate with experienced linear rail manufacturers or suppliers. Seek their expertise in selecting the most suitable rail system based on the application’s specific requirements. They can provide valuable insights, technical support, and customized solutions.

By carefully considering these factors, engineers and decision-makers can make informed choices in selecting and sizing linear rails for specific linear motion applications, ensuring optimal performance and longevity of the system.

Can you explain the principles behind linear rail operation and load-bearing capabilities?

The operation of linear rails and their load-bearing capabilities are governed by fundamental principles:

1. Rolling Contact: Linear rails typically utilize rolling contact elements, such as recirculating ball or roller bearings, between the rail and the carriage. These elements reduce friction and enable smooth motion by rolling along the profiled surface of the rail.

2. Profiled Rail Design: The rail is designed with a specific profile, often featuring raceways for the rolling elements. This profile provides guidance to the carriage, ensuring that it moves along a predetermined path without deviations.

3. Load Distribution: The load-bearing capabilities of linear rails are achieved through the distribution of the applied load across the rolling elements. This design allows for the effective support of loads, both radial and axial, while minimizing stress on individual components.

4. Rigidity: Linear rails are designed to be rigid, preventing deflection or bending during operation. This rigidity is essential for maintaining accuracy and precision, especially in applications where high loads or forces are involved.

5. Lubrication: Proper lubrication is crucial for reducing friction and minimizing wear between the rolling elements and the rail. Lubrication also helps dissipate heat generated during operation, contributing to the overall efficiency and longevity of the linear rail system.

6. Materials and Construction: The materials used in the construction of linear rails, such as hardened steel or reinforced alloys, contribute to their load-bearing capabilities. The choice of materials ensures durability and resistance to wear under various operating conditions.

Overall, the combination of rolling contact, profiled rail design, load distribution, rigidity, lubrication, and appropriate materials enables linear rails to operate efficiently and support varying loads in industrial applications. Understanding these principles is essential for selecting the right linear rail system based on the specific requirements of a given application.

What are linear rails, and how are they used in linear motion systems?

Linear rails, also known as linear guides or linear slides, are mechanical components used in linear motion systems to facilitate smooth and precise movement along a straight path. They typically consist of a rail and a carriage. The rail is a long, rigid structure with a specially designed profile, while the carriage is mounted on the rail and holds the load to be moved.

Linear rails are widely used in various applications, including manufacturing machinery, robotics, 3D printers, and automated systems. They provide guidance and support to the moving components, minimizing friction and ensuring accurate and repeatable motion. The design of linear rails allows for high load-carrying capacity and can accommodate different types of loads, such as radial or axial loads.

Linear motion systems incorporating linear rails offer advantages such as improved precision, reduced wear and tear, and increased efficiency in comparison to traditional sliding mechanisms. The choice of linear rails depends on factors such as load capacity, speed, accuracy requirements, and environmental conditions in the specific application.

editor by Dream 2024-05-16

China manufacturer Hot Sale Linear Guide Rail, Sliding Rail, Linear Slide Rail

Product Description

Linear guide rail, also known as linear guide, sliding rail, linear guideway and linear slide rail, is used for high precision or high speed linear reciprocating motion, and can withstand a certain degree of torque, so as to achieve high precision linear motion (linear movement) under high loads.

The sustained and rapid growth of Chinese economy provides a huge market space for linear guide rail products. The strong temptation of the Chinese market has made the world focus on the Chinese market. In the short decades of reform and opening up, the huge production capacity formed by Chinese linear guide rail manufacturing industry has impressed the world. Along with the continuous expansion of scale from China electric power industry, data communication industry, urban rail transit industry, automobile industry, shipbuilding and other industries, the demand for linear guide rail will also increase rapidly, and there is still huge development potential for linear guide rail industry in the future.

| Shape | Linear shape |

| Size (specification) | As per the drawing from overseas customer |

| Material (steel grade) | Carbon steel or alloy steel |

| Standard | GB, JIS, ASTM |

| Packaging | Bundle with waterproof film or standard pallet |

| Special requirements | Processing according to customer’s design |

Professional manufacturer produces high quality products.

Welcome your sample or drawing for custom-made at our factory.

Much more details, please feel free to contact us.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Special Steel Bar |

|---|---|

| Standard: | ASTM, JIS, GB |

| Composition: | Ferrous Steel Scrap |

| Technique: | Cold Drawn |

| Shape: | Linear Shape |

| Surface Treatment: | Coated |

| Samples: |

US$ 35/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What is the role of linear rail materials and coatings in performance and longevity?

The materials and coatings used in the construction of linear rails play a crucial role in determining their performance and longevity. Here’s an overview of their significance:

Materials:

- High-Strength Alloys: Linear rails are often constructed using high-strength alloys, such as hardened steel or aluminum. These materials provide the necessary strength and rigidity to withstand the stresses of continuous linear motion, ensuring stability and preventing deformation under load.

- Corrosion-Resistant Materials: In environments where corrosion is a concern, linear rails may be made from corrosion-resistant materials or coated with anti-corrosive substances. Stainless steel or specialized alloys with corrosion-resistant properties enhance the longevity of the rails, particularly in industrial settings with exposure to moisture or harsh chemicals.

- Self-Lubricating Materials: Some linear rails incorporate self-lubricating materials, such as polymers with embedded solid lubricants. These materials reduce friction between the rail and carriage, improving efficiency and minimizing wear. Self-lubricating properties contribute to smoother linear motion and extend the lifespan of the rail system.

Coatings:

- Anti-Friction Coatings: Coatings with anti-friction properties, such as Teflon or other low-friction materials, are applied to reduce friction between the rail and carriage. Anti-friction coatings enhance the efficiency of the linear rail system by minimizing heat generation and wear, resulting in smoother and more reliable linear motion.

- Corrosion-Resistant Coatings: Linear rails used in corrosive environments may be coated with protective layers to resist corrosion. These coatings act as a barrier, preventing exposure to corrosive elements and preserving the structural integrity of the rail over time.

- Hard Coatings: Hard coatings, such as nitriding or various forms of surface hardening, are applied to increase the hardness and wear resistance of the rail’s surface. This protects against abrasion and extends the lifespan of the rail, especially in high-load applications.

- Dry Film Lubricants: Some coatings incorporate dry film lubricants that provide long-lasting lubrication to the rail and carriage interface. These coatings reduce friction, enhance performance, and contribute to the overall reliability of the linear rail system.

The careful selection of materials and coatings is essential for tailoring linear rails to specific application needs. By considering factors such as environmental conditions, load requirements, and desired performance characteristics, engineers can choose the most appropriate combination to optimize the performance and longevity of the linear rail system.

What is the impact of proper installation and maintenance on the performance and lifespan of linear rails?

The proper installation and maintenance of linear rails have a significant impact on their performance and lifespan. Here’s how:

Proper Installation:

- Alignment: Correct alignment during installation is crucial for the optimal performance of linear rails. Misalignment can lead to increased friction, wear, and decreased accuracy. Proper alignment ensures smooth and precise linear motion.

- Lubrication: Adequate lubrication is essential to reduce friction between the rail and carriage, preventing premature wear. Proper lubrication during installation sets the foundation for sustained performance and longevity.

- Tightening: Proper tightening of bolts and fasteners during installation ensures the stability and rigidity of the linear rail system. Loose connections can lead to vibrations, affecting accuracy and potentially causing damage over time.

Maintenance:

- Regular Inspection: Periodic inspections allow for the early detection of issues such as wear, misalignment, or contamination. Timely identification of problems enables corrective measures to be taken before they escalate.

- Cleaning: Keeping linear rails clean from debris and contaminants is essential for preventing damage and maintaining smooth motion. Regular cleaning, especially in industrial environments, contributes to the longevity of the system.

- Lubrication Maintenance: Continuous lubrication maintenance is crucial for reducing friction and preventing premature wear. Regularly checking and replenishing lubricants help ensure optimal performance over the lifespan of the linear rails.

Proper installation and proactive maintenance contribute to the overall reliability, accuracy, and longevity of linear rails. Neglecting these aspects can result in decreased performance, increased wear, and a shorter lifespan of the linear motion system.

Are there specific linear rail designs for different applications, like CNC machines or automation systems?

Yes, specific linear rail designs are tailored to different applications based on the requirements of the machinery. Some notable examples include:

- CNC Machines: CNC (Computer Numerical Control) machines demand high precision and stiffness. Profiled rail systems are commonly used in CNC machines due to their exceptional accuracy, load capacity, and rigidity. These systems ensure the precise linear motion required for intricate machining processes in industries like manufacturing and prototyping.

- Automation Systems: Linear rails play a crucial role in automation systems where precise and repeatable linear motion is essential. Profiled rail systems are preferred in high-precision automation applications such as pick-and-place machines, robotic assembly lines, and conveyor systems. These systems provide the necessary accuracy and reliability for seamless automation processes.

- 3D Printers: Linear rails are used in the construction of 3D printers to facilitate the movement of print heads and build platforms. Both profiled rail and round rail systems can be suitable for different types of 3D printers, depending on factors like precision requirements and available space.

- Material Handling Systems: Round rail systems, known for their compact design and cost-effectiveness, find applications in material handling systems. These systems are suitable for applications such as packaging machinery and conveyors, where moderate precision and space efficiency are crucial.

The selection of linear rail designs is influenced by factors such as load capacity, precision, stiffness, and the specific needs of the application. Engineers choose the most appropriate linear rail system to optimize the performance of machinery in diverse industrial settings.

editor by Dream 2024-05-16

China factory CHINAMFG Roller Linear Guide Rail for Automobile Zl Series

Product Description

ZL/ZLL Four-way Equal-load Heavy-duty Narrow Roller Linear Motion Xihu (West Lake) Dis.

Feature 1: The sliding rail and the sliding block are in contact with each other through balls, so the shaking is small, which is suitable for equipment with precision requirements.

Feature 2: Because of the point-to-surface contact, the frictional resistance is very small, and fine movements can be performed to achieve high-precision positioning of control devices, etc.

Feature 3: Because the ball has its own rolling groove, the force on the rotating surface will be dispersed, so it has a larger allowable load.

Feature 4: The linear guide is not easy to generate frictional heat during operation, and is not easy to be deformed by heat, so it is suitable for high-speed motion.

Application:

Automation equipment, high-speed transportation equipment, precision measuring instruments, semiconductor equipment, woodworking machinery

SJAG-ZL ( Four Directional Equal Load Heavy Duty Narrow Type )

| Model | Component size(mm) | Slider size (mm) | Rail size(mm) | |||||||||||||||||||

| H | H1 | N | W | B | B1 | C | L1 | L | K1 | G | M | T | H2 | H3 | WR | HR | D | h | d | P | E | |

| SJAG 25ZL | 40 | 5.5 | 12.5 | 48 | 35 | 6.5 | 35 | 64.5 | 97.9 | 20.75 | 12 | M6*8 | 9.5 | 10.2 | 10 | 23 | 23.6 | 1l | 9 | 7 | 30 | 20 |

| SJAG 25ZLL | 50 | 81 | 114.4 | 21.5 | ||||||||||||||||||

| SJAG 30ZL | 45 | 6 | 16 | 60 | 40 | 10 | 40 | 71 | 109.8 | 23.5 | 12 | M8*10 | 9.5 | 9.5 | 13.8 | 28 | 28 | 14 | 12 | 9 | 40 | 20 |

| SJAG 30ZLL | 60 | 93 | 131.8 | 24.5 | ||||||||||||||||||

| SJAG 35ZL | 55 | 6.5 | 18 | 70 | 50 | 10 | 50 | 79 | 124 | 22.5 | 12 | M8*12 | 12 | 16 | 19.6 | 34 | 30.2 | 14 | 12 | 9 | 40 | 20 |

| SJAG 35ZLL | 72 | 106.5 | 151.5 | 25.25 | ||||||||||||||||||

| SJAG45ZL | 70 | 8 | 20.5 | 86 | 60 | 13 | 60 | 106 | 153.2 | 31 | 12.9 | M10*17 | 16 | 20 | 24 | 45 | 38 | 20 | 17 | 14 | 52.5 | |

| SJAG45ZLL | 80 | 139.8 | 187 | 37.9 | ||||||||||||||||||

| SJAG55ZL | 80 | 10 | 23.5 | 100 | 75 | 12.5 | 75 | 125.5 | 183.7 | 37.75 | 12.9 | M12*18 | 17.5 | 22 | 27.5 | 53 | 44 | 23 | 20 | 16 | 60 | 30 |

| SJAG55ZLL | 95 | 173.8 | 232 | 51.9 | ||||||||||||||||||

| SJAG65ZL | 90 | 12 | 31.5 | 126 | 76 | 25 | 70 | 160 | 232 | 60.8 | 12.9 | M16*20 | 25 | 15 | 15 | 63 | 53 | 26 | 22 | 18 | 75 | 35 |

| SJAG65ZLL | 120 | 223 | 295 | 67.3 | ||||||||||||||||||

| SJAG 85ZLL | 110 | 15 | 35.5 | 156 | 100 | – | 140 | 254 | 349 | – | 14 | M18*25 | 30 | 21 | – | 85 | 73 | 35 | 28 | 24 | 90 | 45 |

| SJAG 100ZLL | 120 | 15 | 50 | 200 | 130 | – | 200 | 286 | 394 | – | 16 | M20*27 | 33 | 23 | – | 100 | 80 | 39 | 32 | 26 | 105 | 52.5 |

| SJAG 125ZLL | 160 | 24.5 | 57.5 | 240 | 184 | – | 205 | 360 | 491 | – | 16 | M24*30 | 40 | 23 | – | 125 | 115 | 48 | 45 | 33 | 120 | 60 |

ZL Type Xihu (West Lake) Dis. Sub Mounting Connection Dimensions

| Fixing bolt size of slide rail | Basic dynamic load rating | Basic static load rating | Allowable static moment | Weight | |||

| (mm) | C(kN) | Co(kN) | MR | MP | MY | Slide | Rail |

| M6×20 | 27.7 | 57.1 | 0.758 | 0.605 | 0.605 | 0.55 | 3.08 |

| 33.9 | 73.4 | 0.975 | 0.991 | 0.991 | 0.7 | ||

| M8×25 | 39.1 | 82.1 | 1.445 | 1.06 | 1.06 | 0.82 | 4.41 |

| 48.1 | 105 | 1.846 | 1.712 | 1.712 | 1.07 | ||

| M8×25 | 57.9 | 105.2 | 2.17 | 1.44 | 1.44 | 1.43 | 6.06 |

| 73.1 | 142 | 2.93 | 2.6 | 2.6 | 1.86 | ||

| M12×35 | 92.6 | 178.8 | 4.52 | 3.05 | 3.05 | 2.97 | 9.97 |

| 116 | 230.9 | 6.33 | 5.47 | 5.47 | 3.97 | ||

| M14×45 | 130.5 | 252 | 8.01 | 5.4 | 5.4 | 4.62 | 13.98 |

| 167.8 | 348 | 11.15 | 10.25 | 10.25 | 6.4 | ||

| M16×50 | 213 | 411.6 | 16.2 | 11.59 | 11.59 | 8.33 | 20.22 |

| 275.3 | 572.7 | 22.55 | 22.17 | 22.17 | 11.62 | ||

| M20 | 460 | 945.2 | 51420 | 45600 | 45600 | 14.7 | 35.2 |

| M24 | 547 | 1330 | 73140 | 61200 | 61200 | 24.5 | 46.8 |

| M30 | 1040 | 1924 | 123176 | 123176 | 123176 | 46 | 84.6 |

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Precision Automation Equipment |

|---|---|

| Material: | Steel |

| Structure: | Linear Motion Transmission |

| Installation: | Automatic Machinery |

| Driven Type: | Roller Linear Drive |

| Carrying Capacity: | Weight Level |

| Customization: |

Available

|

|

|---|

What is the role of linear rail materials and coatings in performance and longevity?

The materials and coatings used in the construction of linear rails play a crucial role in determining their performance and longevity. Here’s an overview of their significance:

Materials:

- High-Strength Alloys: Linear rails are often constructed using high-strength alloys, such as hardened steel or aluminum. These materials provide the necessary strength and rigidity to withstand the stresses of continuous linear motion, ensuring stability and preventing deformation under load.

- Corrosion-Resistant Materials: In environments where corrosion is a concern, linear rails may be made from corrosion-resistant materials or coated with anti-corrosive substances. Stainless steel or specialized alloys with corrosion-resistant properties enhance the longevity of the rails, particularly in industrial settings with exposure to moisture or harsh chemicals.

- Self-Lubricating Materials: Some linear rails incorporate self-lubricating materials, such as polymers with embedded solid lubricants. These materials reduce friction between the rail and carriage, improving efficiency and minimizing wear. Self-lubricating properties contribute to smoother linear motion and extend the lifespan of the rail system.

Coatings:

- Anti-Friction Coatings: Coatings with anti-friction properties, such as Teflon or other low-friction materials, are applied to reduce friction between the rail and carriage. Anti-friction coatings enhance the efficiency of the linear rail system by minimizing heat generation and wear, resulting in smoother and more reliable linear motion.

- Corrosion-Resistant Coatings: Linear rails used in corrosive environments may be coated with protective layers to resist corrosion. These coatings act as a barrier, preventing exposure to corrosive elements and preserving the structural integrity of the rail over time.

- Hard Coatings: Hard coatings, such as nitriding or various forms of surface hardening, are applied to increase the hardness and wear resistance of the rail’s surface. This protects against abrasion and extends the lifespan of the rail, especially in high-load applications.

- Dry Film Lubricants: Some coatings incorporate dry film lubricants that provide long-lasting lubrication to the rail and carriage interface. These coatings reduce friction, enhance performance, and contribute to the overall reliability of the linear rail system.